MXQ progressive cavity pumps are self-priming, positive displacement pumps, which are used for pumping a wide range of liquids including highly viscous, aggressive fluids with entrapped air, or neutral fluids, or fluids with fiber and solid content. Our pump designs are designed for low to high flow applications, with various pressure handling requirements.

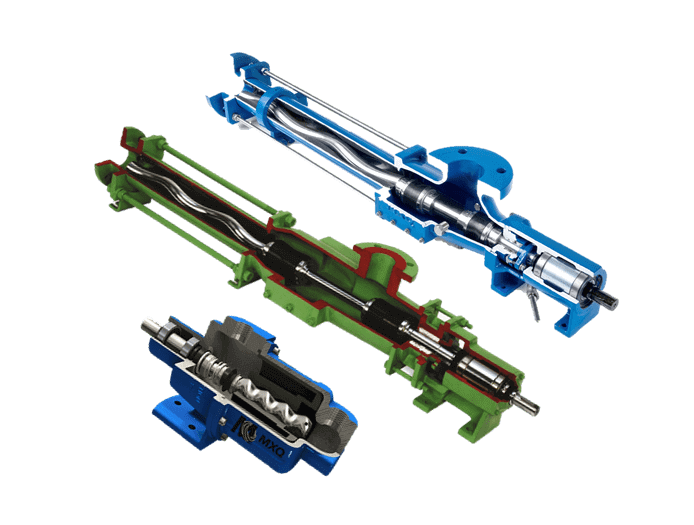

MXQ progressive cavity pumps consist of two parts; the rotating eccentric screw and the stationary stator. The rotor conveys the medium with low pulsation and vibration through the stator. The pump materials of construction will be based upon the application.

We provide the following models of progressive cavity pumps:

1. Bornemann® Equivalent Pumps: 100% Bornemann equivalent progressive cavity pumps. Capable of handling viscosities up to 1,000,000 cSt, solid sizes up to 3ʺ, pressures up to 360 PSI, and flow rates up to 1,400 GPM.

2. Netzsch® Equivalent Pumps: Netzsch® inspired progressive cavity pumps that are provided with various options like cardan joints, pin and bush joints, high pressure, high flow, and close-coupled models.

3. Moyno® Equivalent Pumps: Moyno® equivalent progressive cavity pumps are designed for various industrial applications.

Beneficial Features of MXQ Progressive Cavity Pumps:

The following features of progressive cavity pumps provided by us have immensely contributed towards their popularity in various industries:

Strict quality standards and test procedures at MXQ assure that you receive the best performing progressive cavity pumps. Even after the initial sale we continue to provide support to ensure optimum performance in various service conditions.

What are Progressive Cavity Pumps?

A progressive cavity pump is one of the important types of fluid transfer equipment used in various process industries. This pump is a positive displacement pump that transfers fluid amounts through cavities of discreet shape. The pump materials of construction will be based upon the application. The progressive cavity pumps are also referred to as eccentric screw pumps, cavity pumps or single screw pumps.

Working Principle of Progressive Cavity Pumps

A progressive cavity pump follows a principle of positive displacement. There is a suction inlet that feeds into a long casing, which holds stator assembly, as well as a helically shaped worm rotor. The helical rotor is positioned offset to the stator. The cavities are created when the rotor comes in contact with the stator surface. As the rotor starts moving in a typical eccentric fashion, the cavities are produced, which draws the fluid. This fluid progresses through the assembly, and is finally discharged through the specially designed discharge port.

The rotor of the progressive cavity pump is specially made of stainless steel or hardened alloy steel, and feature a chrome plating, which offers excellent resistance against abrasive and corrosive materials. MXQ progressive pumps have rotors made of C45 hard chrome tool steel, 1.4571 SS 316, and 1.4462 SS.

Stators are metal tubes, which feature internally molded cavities of natural or synthetic rubber. We provide a wide range of choices, when it comes to cavities. Some popular rubber materials used include Buna, Perbunan, White Perbunan, Therban, Viton, Butyl rubber, EPDM, CSM – Hypalon, etc.

When to Use Progressive Cavity Pumps

MXQ’s progressive cavity pumps are versatile equipment, which are widely used across various applications. These pumps offer excellent abrasion resistance in pumping applications involving aggressive fluids. The progressive cavity pumps can be used in pumping applications involving:

In addition to the above-mentioned, the pumps are also ideal to use in the following conditions:

MXQ’s progressive cavity pumps packages are effective due to several benefits offered by them. These packages are developed to offer space efficiencies, minimize installation hassles, and maximize productivity. We provide the progressive cavity pumps in following packages:

Our team has a vast experience in design and fabrication. We can design these progressive cavity pump packages to meet any complex requirement.

MXQ Progressive Cavity Pumps Design

Progressive cavity pumps are nowadays available in different geometries, owing to their increasing use in various industrial applications. The degree of product entry into the cavity, the degree of sealing and efficiency between the cavities vary across these geometries. The standard geometry is suited for highly viscous and thick material, however, MXQ progressive cavity pumps have elongated geometry with a large surface contact between the stator and the rotor. This large surface contact helps improve the efficiency of the progressive cavity pump.

The following are salient innovative design features of the MXQ progressive cavity pump

The elongated profiles have helped minimize thrust loads on the bearings and joints, reduce starting torque requirements, as well as shearing on the load.

Universal joint used in MXQ progressive cavity pumps is lubricated with synthetic temperature stable lubricant, and is offered with a 3-year warranty.