Elongated Profile Stator & Rotor

Recognizing the need for longer pump life in progressive cavity (PC) style pumps, MXQ has standardized on a unique rotor and stator profile that has proven extremely beneficial to PC pump users. Simply stated, the pitch of the rotor and stator has been increased while the overall diameter has decreased. One key factor in determining the overall life of the PC pump is the peripheral surface speed of the rotor against the stator (rubbing velocity), this new profile was designed to reduce the rubbing velocities, and increase the pump’s rotor/stator life expectancy. Testing proves the new profile increases the life of the pump by as much as 40% over standard profiles.

Additionally, the elongated profile rotor/stator geometry are lower thrust loads on the joints and bearings, lower starting torque requirements and reduced shearing imparted on the fluid.

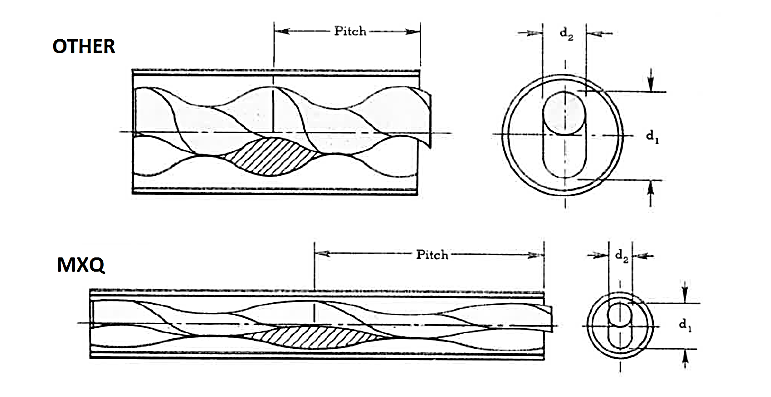

The image above shows two different rotor/stator profiles with the total volume of each complete cavity approximately the same. Because PC pumps are positive displacement pumps, their flow rate is directly proportional to the volume of each cavity and the rotational speed (RPM) of the rotor. The performance delivered at the same speed for both profiles is the same. Examine the image above further; you can see the rotational diameter (d1) and the diameter of the rotor (d2) are the same in the MXQ design. The results is that for a given speed, the peripheral surface speed of the rotor on the stator (rubbing velocity) is lower with the MXQ design. Since rubbing velocity is the major factor in the life of the progressive cavity pump, our design offers less wear and longer life for the rotor and stator.

Viewed from the end of each pump you can see the MXQ design has a smaller cross sectional area for the stator cavity than conventional designs.

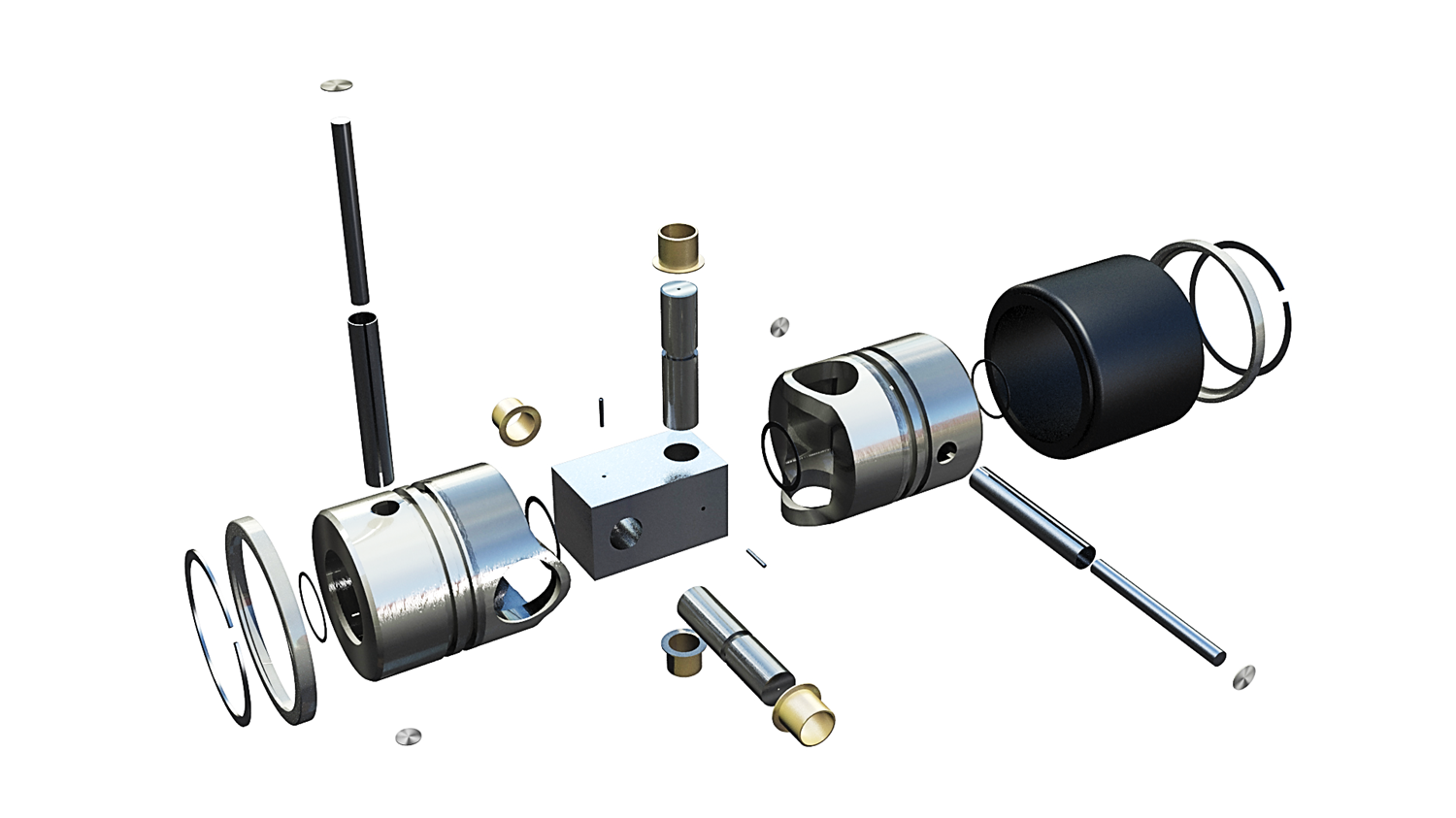

Universal Cardan Joint (3 year warranty)

The rotor of a PC pump turns around three different centers of rotation. Since the rotor’s centerline is eccentrically offset from the drive shaft centerline, they cannot simply be joined together; a flexible type drive connection is required.

In the first stages of progressive pump development, it was accomplished by utilizing a pin type flexible joint. One pin was installed at either end of the connecting rod. The flexible motion of the rotor required the rod to rotate on one pin while rocking on the other. O-rings or lip seal sealed the pins from the process fluid. The amount of rocking had to be limited the angularity that could be tolerated was very low. To compensate for this the pin joints were mounted on long connecting rods. In order to keep the pump length from becoming too long, a hollow drive shaft tube then had to be put over the connecting rod with the pump bearings installed on the outer diameter of the hollow tube. This did prove effective in decreasing the pump length, however solids and stringy material would clog the hollow tube, making maintenance difficult.

When PC pumps were used for abrasive or in applications with suspended solids, the pin joint design quickly failed due to solids getting into the pin joint and eroding the pin. To solve this problem a gear type flexible joint was developed to replace the pin joint. The hollow tube design was kept to avoid having to change the entire pump configuration, it’s inherit disadvantages of clogging and inaccessibility remains a problem today.

Considering the problems with the pin and gear joint and the hollow shaft MXQ has standardized on the Universal – Cardan joint design. This type joint allows for greater angularity, and reduces the length of the connecting rods and eliminated the need for the hollow tube configuration. It is a double doweled universal joint, one of the most common and time-proven mechanical transmission devices used today.

This type of drive connector can be found transmitting power efficiently on everything from automobiles, massive off road vehicles and heavy machinery. It is simply rugged and the best of all, it is easy to access and easy to repair.

MXQ universal joint is lubricated with heavy synthetic temperature stable lubricant, an elastomeric boot made from the same material as the stator is fitted over the assembly to seal the universal joint from the pumped fluid and hold the lubricant in place. This design has proven itself to be very reliable and comes with a standard warranty of 3 years.

MXQ – Standard Features

- Cardan Style Universal Joints – 3 Year Warranty.

- Elongated Profile.

- Stainless Steel Internal Shafting.

- Bronze Lantern Ring for packing flush.

- Hand-Hole Clean Out access port on all cast iron pumps size EH600 and larger.

- Drain pipe on the stuffing box.

- Stuffing box flush connections.

- Stainless Steel packing gland T-bolts.

- Stainless Steel tension rods.

- Fitting on discharge flange and suction housing for pressure gauges.