Liquid ring vacuum pumps are increasing in popularity and availability nowdays. These pumps are also referred to as liquid piston rotary pumps and water ring water piston pumps. Why so? Because they utilize liquid as a piston, and water is the most common choice of liquid in these pumps, hence the name. Nowadays, these pumps are widely preferred because they can perform in the harshest environments, and ensure sustainable productivity. Of course, there are also several benefits that they offer. Are you intrigued to know what they are or how these pumps work? Read this post to learn more.

Understanding How Liquid Ring Vacuum Pumps Work

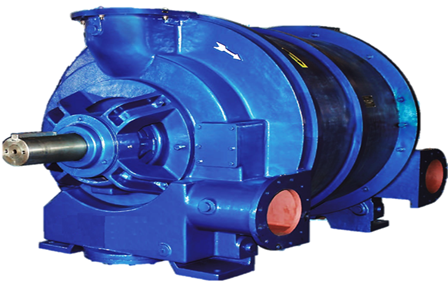

The liquid ring pump features an impeller, which is positioned eccentrically to the cylindrical housing of the pump, and in between two port plates. In this pump, the vacuum is created using a liquid such as water, water-methanol mixture, and oil. The pump is filled with liquid up to a quarter of its volume. The port plates feature shaped holes, which enable easy discharge and suction of the vacuum pump when it is in action.

When the impeller is in the rotation, the liquid starts moving outwards, and creates a void space. The liquid is turned into motion, and it forms a ring outside, thus, the pump gets its name. The motion of the liquid is initiated by a centrifugal force. The liquid ring is eccentric to the impeller, and concentric to the housing of the pump.

During the rotation of the pump, gases are sucked from the suction or inlet port, then compressed, and discharged through the discharge port. Owing to its large number of blades, the operation of the pump is continuous.

Advantages of Liquid Ring Pumps – On the Basis of Design

As with any other industrial pumps, liquid ring vacuum pumps also have typical advantages owing to their designs. The pumps are classified into three types – Once Through System, Partial Recirculation System, and Total Recirculation System.

- Once Through System: In this system, the sealing liquid enters into the system once. The liquid that is discharged from the pump is directed to a separator vessel. In the separator vessel, the gas is separated from the liquid, and finally, the liquid is drained. This is a simple system, where no recovery or recirculation of the liquid takes place.

Advantages: The liquid ring system- Demands no major initial costs

- Is suited for less critical service projects

- Partial Recirculation System: This system is similar to once-through system. However, the only difference is the separator is used for recirculating the liquid discharged from the pump. Makeup water is introduced in the separator tank to perform recirculation. The liquid discharged from the separator becomes equal to the quantity of the makeup water added. This discharge is conducted through an overflow connection, which is placed in the horizontal plane, in the shaft centerline of the pump. The fresh sealing liquid introduced to the pump helps maintain its proper temperature. This temperature maintenance contributes to pump maintenance, as well as minimizes the chances of cavitation.

Advantages: This liquid ring pumping system:- Demands no major initial costs similar to the once-through system

- Consumes less sealing liquid

- Is suited for applications which demand high seal-liquid conservation.

- Total Recirculation System: In this liquid ring pumping system, the sealing system is completely recirculated in the system. A heat exchanger is used to remove the heat produced in the system. Next, the sealing liquid is re-introduced into the vacuum pump. In this system, the level of the sealing liquid is maintained slightly below the centerline of the pump shaft. This is done to prevent the pump motor from overloading during the start. This may damage the pump in the long run. However, if the pressure drop in the system is high, then it is compensated using a circulation system.

Advantage: This liquid ring pumping system:- Is designed for high vapor/gas services

- Consumes less sealing liquid

Common Advantages of Liquid Ring Vacuum Pumps

The following advantages of liquid ring pumps have contributed to their immense popularity and rising demand across various industries.

- Requires No Lubrication: The liquid ring pumps require no regular lubrication, because there is no metal-to-metal contact.

- Ideal for a Variety of Applications: Liquid ring pumps can be employed for vacuum as well as compression jobs, which makes them popular across various industries. As with liquid, the pump uses its impeller to compress the gas. These pumps can be employed for applications such as vacuum distillation, moisture extraction, vacuum condensation, air or ash handling, evaporation, mineral beneficiation, and for separating water from paper pulp.

- Low Maintenance: Unlike other mechanical pumps, these pumps are driven by liquid ring technology, and have only one rotating part – the impeller. This reduces the need for regular maintenance.

- Suited for Various Types of Fluids and Explosive Gases: These pumps are designed to handle a variety of fluids. Made of durable materials, these pumps are designed to withstand combustible vapors or gases without affecting their performance. The gases in the cavity of the pump are compressed at the same temperature. Thus, the pump is capable of pumping explosive and flammable gases.

- Compact Designs and Durable Construction: With space constraints becoming a big issue, the pumps are now available in compact designs. Many of these pumps such as MXQ PS Series and MXQ Premier PV Series are made of cast iron. However, these pumps are also available in SS 304 and SS 316 materials.

Owing to their increasing popularity, today, it is easy to find these pumps in various specifications. However, it is important that you source them from a reliable brand. MXQ is a trustworthy provider of liquid ring vacuum pumps in the US. Our MXQ PS Series and MXQ Premier PV Series liquid ring vacuum pumps can be used across various industries such as pulp and paper processing plants, chemical and pharmaceutical plants, food and beverage waste processing units, and so on.